OUR PRODUCTION PROCESS

In the production process of Sierra Gorda SCM, the optimization of resources and the use of new technologies is essential to address the challenge of low-grade mining.

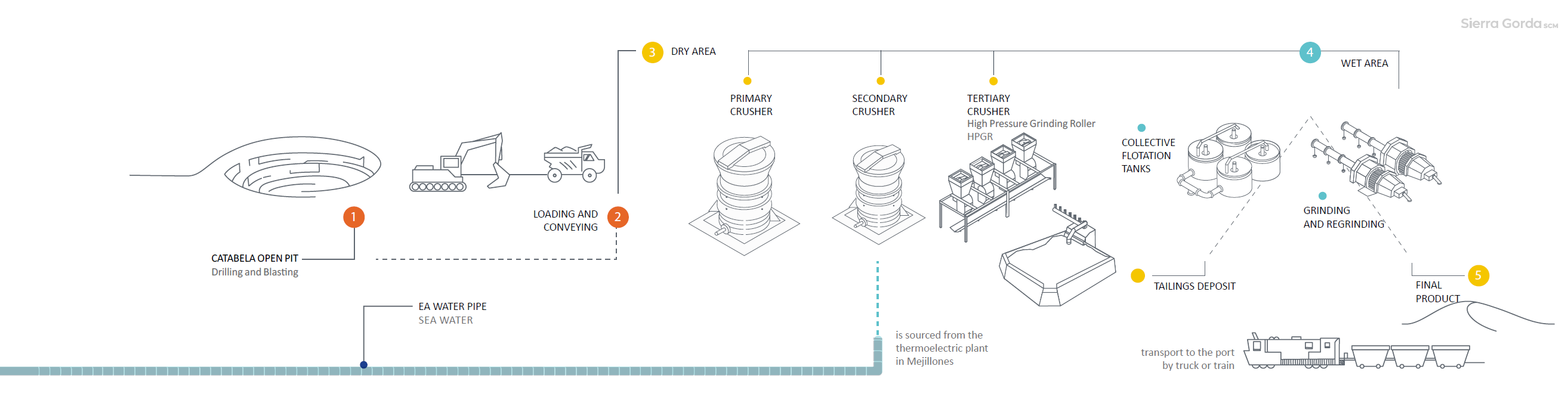

The mine operates in a traditional manner, using open pit methods involving drilling and blasting. The loading is carried out with shovels, while land transport is carried out by high-tonnage extraction trucks, responsible for bringing the ore to the crushing area and the sterile ones to the landfills.

After the crushing process, the sulfur mineral is directed toward the concentrator plant. On the other hand, the oxidized ore is stored in piles with the potential to be processed in the future by leaching.

The crushing and processing facilities consist of a collective plant that produces copper and molybdenum concentrate. This includes primary crushing, conveyor belts, mineral storage dome, secondary crushing, high-pressure tertiary crushing with HPGR (High Pressure Grinding Roller), grinding, bulk flotation, and regrinding. Then, a selective flotation process follows in the molybdenum plant that separates copper and molybdenum concentrates, a process that includes conventional and column flotation, molybdenum concentrate thickening and filtering, and molybdenum concentrate bagging facilities.

In addition, it has a copper concentrate filtering process, with loading and unloading facilities for trucks, a tailings thickening system and a tailings deposit.

The water supply for the processes of production of Sierra Gorda SCM comes from the sea and goes through a cooling system in the Mejillones thermoelectric power plant. Subsequently, the water flows into a swimming pool in the mining operation, after traveling an aqueduct of an extension of 143 kilometers.

The pumping system is designed to provide a maximum flow of 1,500 liters per second of water and consists of three stations: Costa, PS1 and PS2. The seawater used in production processes is in its pure natural state, that is, without desalination. Only a small percentage is desalinated for use in the molybdenum plant and for consumption in the mining camp. This desalination process involves a pre-treatment of reverse osmosis followed by a post-treatment of reconditioning and re-mineralization.

The electricity supply of Sierra Gorda SCM is in charge of the company AES Andes and its facilities have been in operation since 2014. It begins at the Encuentro substation and propagates to the mine’s electrical substation, through a 220 kV high-voltage line of an independent three-phase dual circuit.

An important milestone of Sierra Gorda SCM in 2023 was to achieve 100% of the electricity supply for its operations from certified renewable sources (solar, wind and hydroelectric).

Finally, copper and molybdenum concentrates are transported by land, either on trains and/or trucks, to the unloading and shipping facilities at the Port of Antofagasta International Terminal (ATI) and/or Puerto Angamos, a task carried out by specialized companies with high standards of safety and environmental care.